Development and Construction of Containers

The logistics systems of the Logtech GmbH are checked by the strictest of German quality standards and produced in Eastern Europe. Apart from steel productions, the Logtech GmbH also develops and produces all plastic pieces in the field of injection molding and deep drawn components.

This way, individual solutions can be realized affordably and quickly.

Development

Logtech GmbH and their business partners work closely together on the development of transportation systems. This includes the individual creation of transportation solutions and containers.

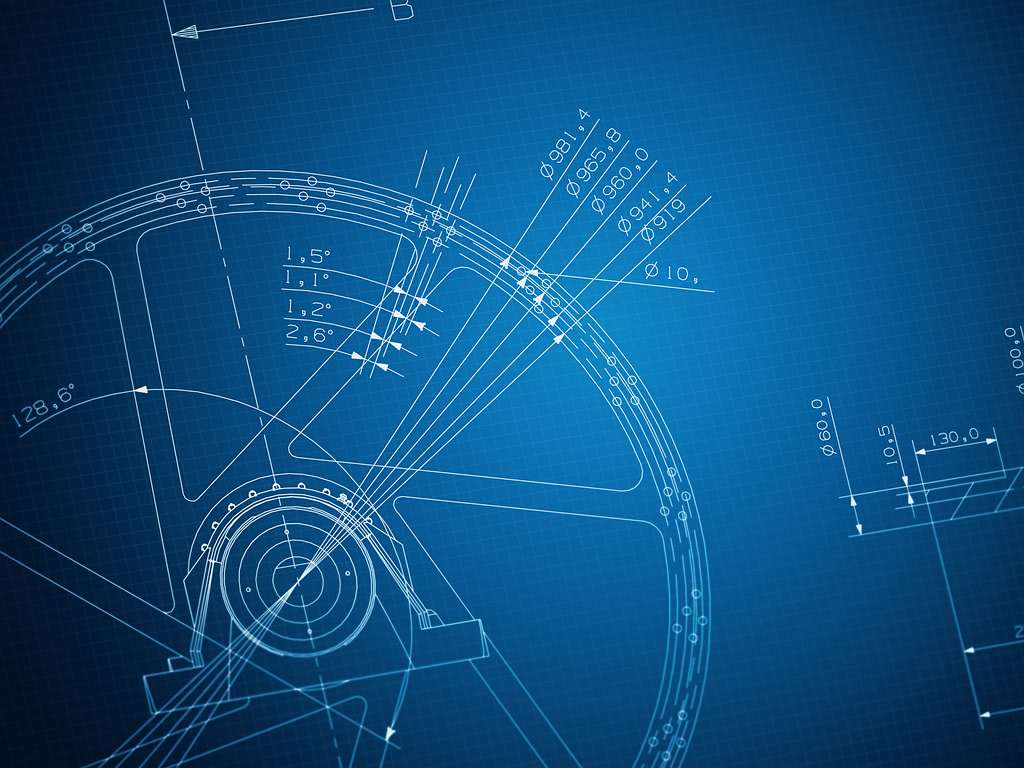

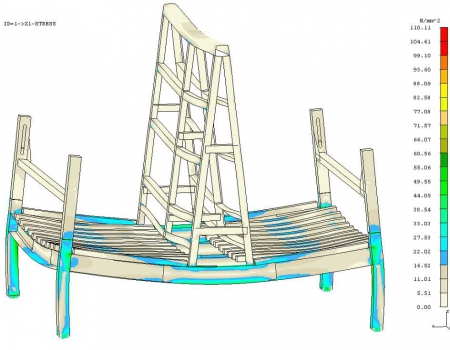

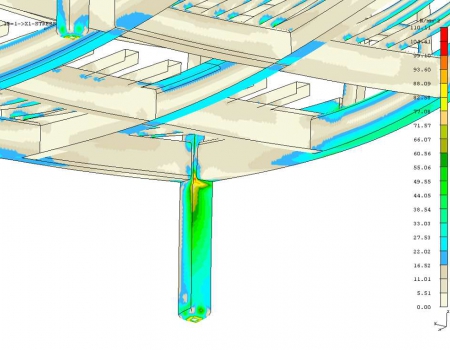

The collective know-how of each specialized partner allows for the client to receive an optimized, flexible, and quick solution. The state of the art CAD systems (autoCAD) and CATIA V5 are used in producing high quality products. At the same time, we offer the option of dynamic stress analyses already during the course of the development.

Stress Analysis

Construction

All products are made in Poland. Some members of the highly qualified team was educated and trained in Germany, and now oversee a broad network of subcontractors, currently counting around 300 employees.

The network of affiliated companies can process around tons of steel per month. The Logtech GmbH combines competitive production conditions with highest standards in quality and flexibility.

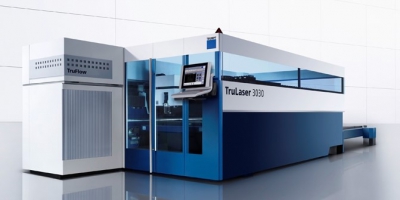

Machinery

A selective overview of our production machinery:

- CNC-controlled profile cutting lines

- Laser system including the option of cutting in closed profiles

- CNC bending press

- CNC machining center

- Plasma and water jet cutting centers

- MIG/MAG welding work places

- Welding robot

- Powder coating facility including pretreatment (phosphating)

- Wet varnish

- Galvanization